Koehler Instrument Company

أجهزة اختبار الجودة وخدمات الدعم الفني لمختبرات البحث والاختبار تخصص Koehler منذ عام 1925. التي تلبي احتياجات الاختبار

الخاصة بالعملاء وهي محل التركيز الأساسي للأعمال ، وهذا هو السبب في أن شركة كوهلر للأدوات هي منتج ومورد رائد للصناعة البترولية

والوقود الصناعي وأجهزة البتروكيماويات في جميع أنحاء العالم.

Automatic Cloud and Pour Point Analyzer

Test Method:- ASTM D5771 -

جهاز اختبار ASTM D5771 - للمنتجات البترولية ووقود الديزل الحيوي الشفاف

Automated Air Release Value Analyzer

Test Method:-جهاز اختبار قدرة التوربين أو الزيت الهيدروليكي أو زيت التشحيم.

Automated Air Release Value Analyzer

Test Method:-جهاز اختبار قدرة التوربين أو الزيت الهيدروليكي أو زيت التشحيم.

Automatic Microscale Vapor Pressure Analyzer

Test Method:-جهاز اختبار ASTM D5191 يحدد ضغط البخار الكلي في الفراغ للمنتجات البترولية السائلة المحتوية على الهواء المتطاير ، بما في ذلك وقود اشتعال شرارة السيارات مع أو بدون أكسجين.

Automatic Microscale Continuously Closed Cup Flash Point Analyzer

Test Method:- جهاز اختبار ASTM D6450 لتحديد نقطة اشتعال زيوت الوقود وزيوت التشحيم والمذيبات والسوائل الأخرى

Automatic Pensky-Martens Closed Cup Flash Point Tester

Test Method:- جهاز لاختبار تحديد نقطة الوميض للديزل الحيوي ، والوقود المقطر ، وزيوت التشحيم الجديدة ، وزيوت الوقود المتبقية ، ومخلفات القطع ، وزيوت التشحيم المستخدمة ، ومخاليط السوائل البترولية مع المواد الصلبة ، والسوائل البترولية التي تميل إلى تكوين طبقة سطحية أثناء الاختبار.

AC100 Petroleum Colorimeter

Test Method :- طريقة الاختبار D156 لتحديد لون الزيوت المكررة مثل المحركات غير المصبوغة وبنزين الطيران ، ووقود الدفع النفاث ، والنفثا والكيروسين ، بالإضافة إلى الشموع البترولية والزيوت البيضاء الصيدلانية.

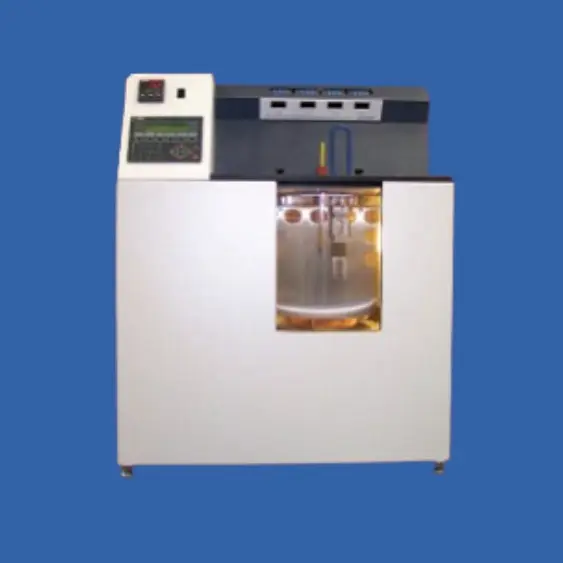

KV1000 Digital Constant Temperature Kinematic Viscosity Bath

حمام درجة حرارة ثابتة لاختبار اللزوجة الحركية للمنتجات البترولية. يستوعب ستة جولة 2 " (51 مللي متر) ضياء. حاملي مقياس اللزوجة. درجة حرارة الحمام

KV3000 and KV4000 Constant Temperature Baths with Integrated Digital Timing

LKV3000 and LKV4000 Refrigerated Constant Temperature Baths

Viscometer Cleaning and Drying Apparatus

BV4000 Brookfield Viscosity Air Bath